Piezo Shock Show #9: Why do piezo benders generate so much voltage?

Welcome to The SHOCK Show #9. In this episode, I will give a simple but important demonstration regarding piezo bending transducers. Why does bending generate so much more voltage than axial forces?

The discussion in this episode will focus on off-resonance applications.

Read on or watch the episode here: https://youtu.be/zAVU1niDfd0

Bending is the simple lever of piezoelectric transducers

In comparison to axial loading and longitudinal transducers, piezoelectric benders are predisposed to generate a significant amount of displacement with an applied voltage and a significant amount of voltage for an applied force.

Piezoelectric ceramics, especially PZT, typically generate nanometers of displacement for tens of volts applied. But don't dismiss these nanometers - they are unstoppable. The blocking force of these materials are relatively huge. That being said, many applications, especially low frequency/off-resonance applications, require millimeters of displacement, but less force.

The magic of bending

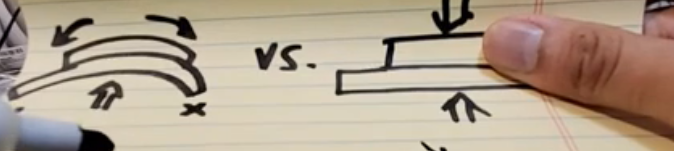

The magic of bending is that displacement accumulates across the length. by attaching a passible material to a piezoelectric element, the neutral axis is shifted and the axial displacements of a piezo now create a movement and hence bending. Without shifting the neutral axis, a piezo element will never undergo bending under an applied voltage nor see voltage generated when subjected to a moment.

What bending does is shift the high force-low displacement nature of piezoelectric materials in a low force-high displacement function. You can think of it as a permanent change in the transmission of displacement and force, much like shifting gears, only permanently.

On with the demo!

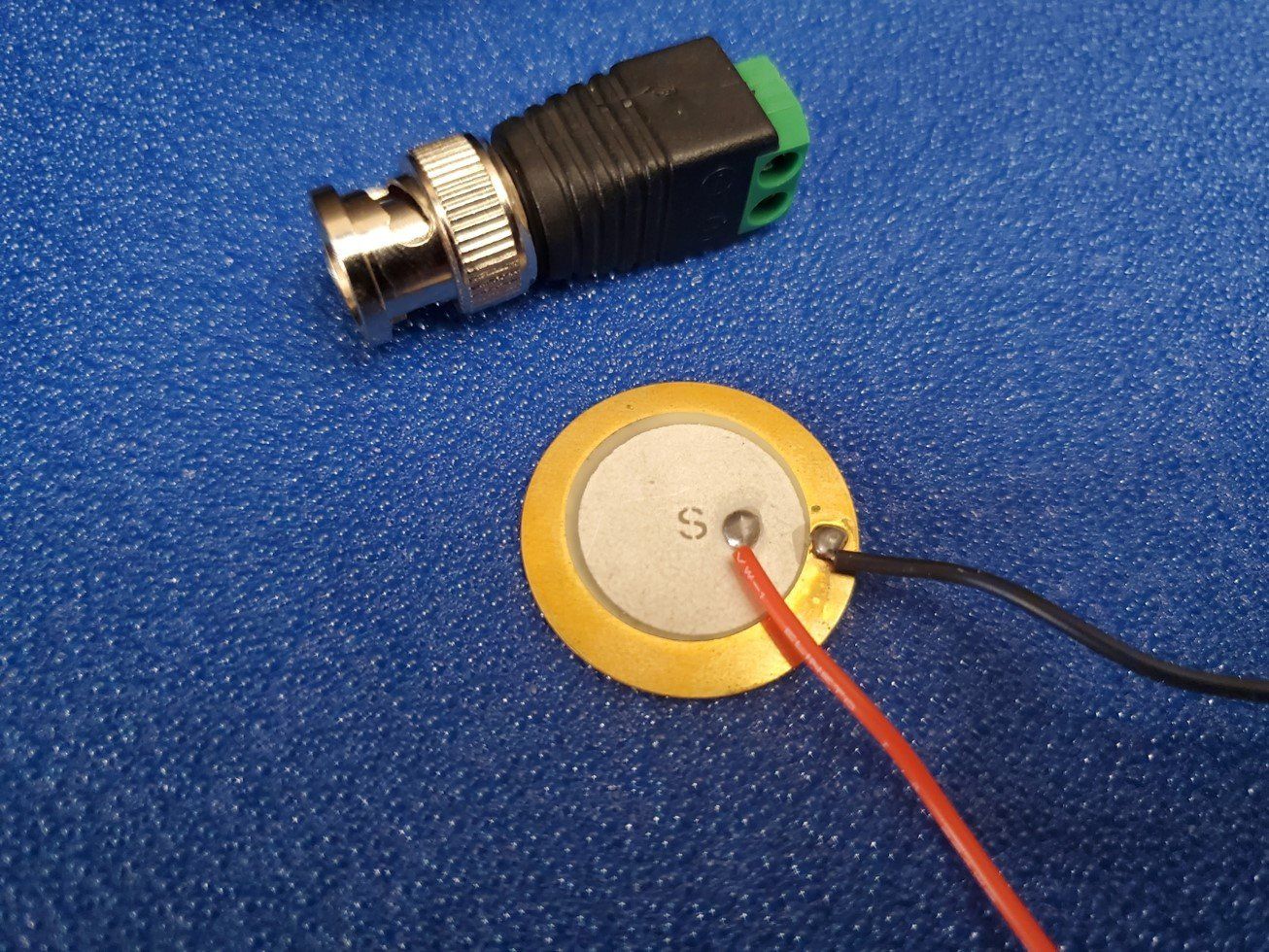

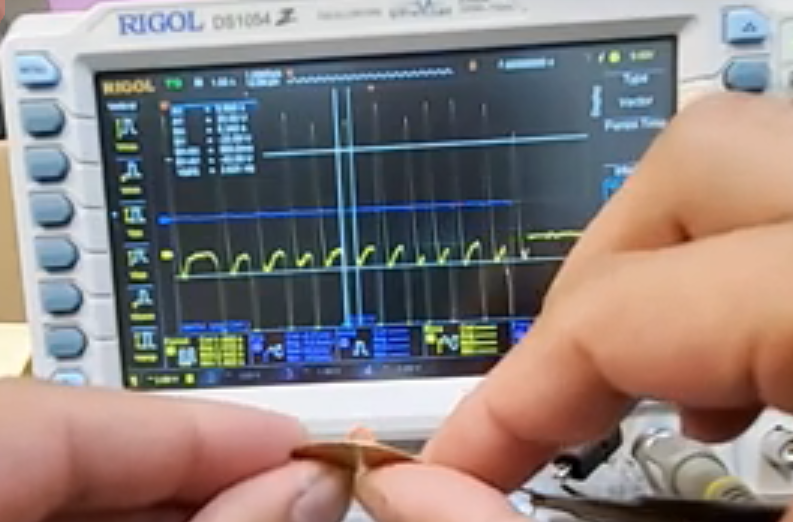

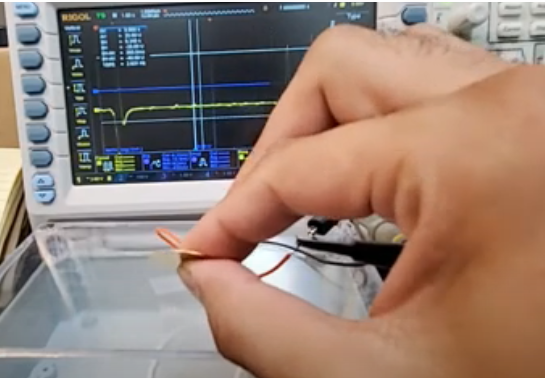

In this demonstration, I've hooked up a piezo buzzer (piezo element bonded to a brass shim). When I apply a light bending force, huge voltage is generated (and also large displacement). When I squeeze axially really hard, only a small voltage is generated.

The only way to effectively couple a transducer to air is to achieve large displacement. This is why bending transducers having large displacement, like a buzzer, are used for sound generation and microphones.

Ultrasonic applications of bending

On example of an air bending transducer is the ultrasonic range finding transducer. It has a unimorph (one piezo layer and one passive layer) bonded to a cone. That being said, you won't be using a bender for welding or other high power applications because benders have low resonance frequencies due to their low stiffness.

I'll end this article with this: Every design topology has its place in the universe.