Where did we go wrong!

Root cause analysis of failure, variability, or other undesirable effects unavoidable in ultrasonic transducer product development.

What is avoidable, in many cases, is realizing that your product's issues from customer complaints. That being said, many times we discover issues regarding our device from customers because our production testing methods are incomplete to sufficiently guarantee performance.

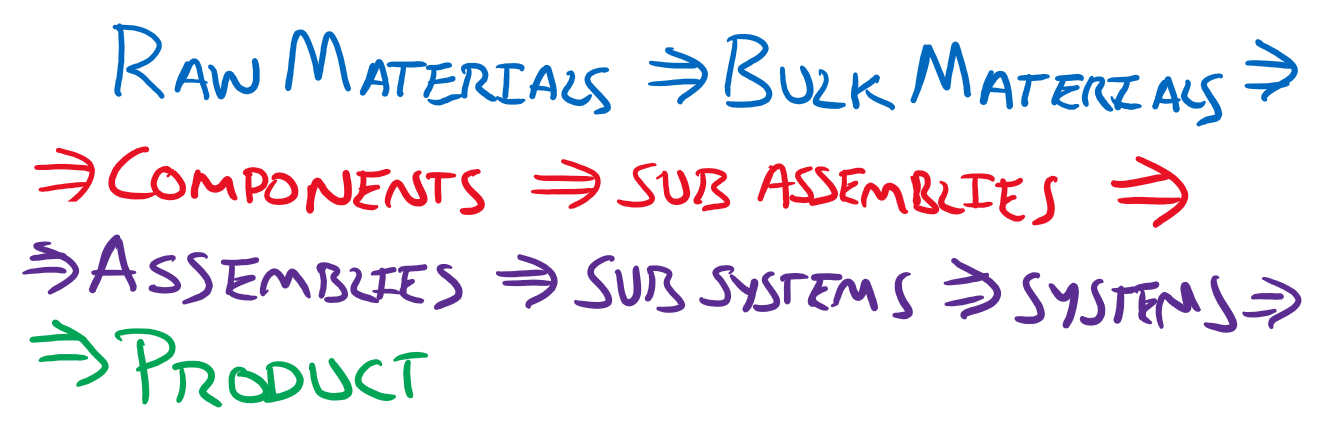

There are many steps going into the production of a product, and missteps at any portion of the chain is going to result in a faulty final device.

In the ideal case, I recommend to seek out anomalies through testing as far back as possible. This could mean comprehensive testing of piezoelectric crystals before assembly and testing bulk metal materials before machining. It could also even mean composition analysis of each batch of crystals.

Some of these suggestions may seem extreme, but even if these tests save your company from doing ONE root cause investigation, it will reward you SEVERAL TIMES MORE than the expenses of your comprehensive test regimen.