Piezo SHOCK Show #11: How can I measure variability between transducer from different manufacturers?

Welcome to The SHOCK Show #11. In this episode, I will answer the question: "Do transducers between manufacturers have a lot of variation and how can I measure it ?"

Read on or watch the episode here: https://youtu.be/EI0XlicSO48

Variability in ultrasonic transducers between manufacturers

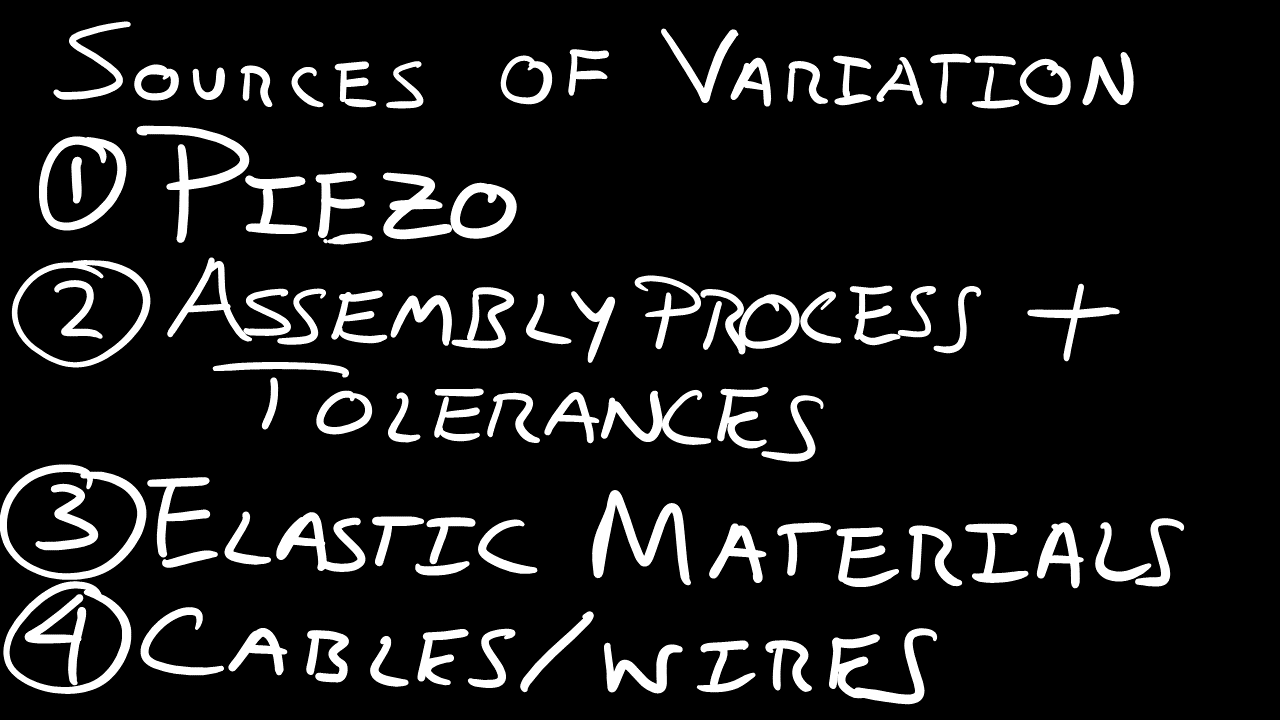

There are 4 areas where variability creeps into a transducer production operation. They are (1) Piezo ceramic property variability (2) Assembly process and tolerance variability (3) Variability in properties of the elastic materials and (4) Variability in behavior of wires, cabling, and connectors.

(1) Piezo ceramic property variability

Most transducer manufacturers that have been around long enough have almost certainly encountered significant variability issues due to piezo ceramic property variability. A swing in properties up to 30% is not hard to believe. If you have not already, subscribe to my blog and receive my guide to the top three challenges in ultrasonic transducer development. Link to subscribe is here: ultrasonicadvisors.com/blog-home

(2) Assembly process and tolerance variability

Interfaces and component build up plays a huge role in determining losses, resonance frequencies, stability of the transducer over time, and spurious behavior. In the life of a product, non-experts can make improvement decisions which inadvertently impact the consistency of the product. Many ultrasonic transducers are also made "by hand", and thus have an inherent variability between assemblers and between build sites.

(3) Variability in properties of the elastic materials

Elastic materials used in transducer construction are typically the most stable in terms of variability, especially metals, however, their loss properties are sensitive to microstructure, so in an ideal sense their properties should also be monitored. Epoxy is a big wild card in this area. If any problem occurs in your company's transducer, you will never sound dumb if you say the problem might be the epoxy.

(4) Variability in behavior of wires, cabling, and connectors

Finally, cabling, connections, and wires add stray capacitance, inductance, and resistance. This will most certainly mess with your transducer's performance, especially in sensor applications. Controlling the stray electrical behavior of your electrical connections, wires, and cables will ensure consistent performance of your sensor.

You still did not answer the question!

Oh yes, let me get back to the question:

Do transducer between manufacturers, that are apparently supposed to be the same thing, have significant differences?

Yes they can, especially because each manufacturer will be dealing with their own version of the top four reasons for transducer variability that I just described. It is important to note that although manufacturers are using equivalent piezo ceramics for similar applications, no two manufacturers can provide the same exact piezo material. Not only that, but the properties have significant variability at even a single manufacturer.

And the next question:

How can I determine the differences between transducers?

There are both analytical and system level ways to do it. The system level methods involve the final application, which is already familiar to the questioner, so I'll skip that. However, the analytical way to determine transducer differences is the ultizie impedance analyze of the transducer and to compare summary parameters. I have a course on that subject here: ultrasonicadvisors.com/impedance_course

However, the point of this article was not to lead you down a rabbit hole to think the only way you can get practical steps for evaluation is to purchase my $1,350 course.

Here is the power action you can do to easily stay on top of your understanding of the differences of your transducer: measure the capacitance

The capacitance of an ultrasonic transducer indicates toward the electromechanical coupling of the device. It is the most dead simple way to understand transducer differences. In most cases, you can apply the golden rule